The new L-Series from CompAir

User Manual Screw Air Compressor L07-L22 GB CDN USA Id. 100013552 / 00 - Dezember 2007.

Well known in the industry for quality and reliability, CompAir continuously develops the L-Series achieving cutting edge performance and efficiency.

Acces PDF Compair Delcos Xl Manual figures and proportions of various types of joints like sleeve and cotter, gib and cotter, foundation bolt etc. New chapter on levers. Figures for applications for power screws like screw jack, machine vice, gate valve, turn-buckle etc. Principles Of Unit Operations, 2Nd Ed. Compair Delcos Xl Manuals guide torrent delcos xl manual manual craig manual compair l 75 delcos 3100 - user's guide 97 delcos controllers - rotary screw air compressor controllers pontoon compair delcos 3100 service manual - books online jd manuals compressor delcos pro controller manual 250 service lubricated screw fixed speed compressors.

The new versatile range from 30 to 45 kW can be configured to meet the customers’ efficiency requirements. Microsoft windows media player for windows 10. The E-models feature a larger airend delivering highest efficiency levels. The regulated speed models save energy by matching the output to the plant air demand. All fixed speed models are available with integrated dryer option.

Compair Delcos Xl Manual

Benefits

An investment that pays off

The E-Models of the L-Series feature an extra large airend with optimised rotor tip speed achieving up to 6% energy savings.

The largest cost component of a compressor is the energy to run it. The reduction of energy costs significantly impacts on the total costs of ownership.

The additional investment costs for this range of super efficient compressors will pay back in many cases in less than 12 months. The extra large airend also has a longer life expectancy.

Regulated speed compressors

The regulated speed models can efficiently and reliably handle the varying air demand found in most plant air systems. The annual cost of ownership can be significantly reduced using regulated speed technology.

CompAir RS features are your benefits.

The L-RS Series products are designed to obtain the greatest efficiency across the entire operating range.

Wide regulation range – No cycles means substantial energy savings.

Perfect motor – drive – airend design – High efficiency across broad flow range.

Design

Exceptional reliability and performance

- Large surface after cooler

Optimum cooling to ensure low operating and discharge temperatures. - Next generation separator filter

Amply dimensioned filtration for constant performance throughout the lifetime delivering an oil carryover of less than 3ppm. - High efficiency electric motor

The compressors are equipped with an energy saving IE4 electric motor as standard. - Thermostatically controlled motor driven fan

Highly efficient and extremely quiet fan allows compressor operation in the work place, plus the use of maximum duct length without further assistance. - Highest quality connections

Solid hoses and pipe connections with viton victaulic couplings increase reliability and are easy to maintain.

Controller

Delcos XL innovative touch screen compressor controller

The Delcos XL with its high resolution touch screen display is extremely user-friendly and self-explanatory. All functions are clearly structured in five main menus and are intuitively visual. The multilingual Delcos XL control system ensures reliable operation and protects your investment by continuously monitoring the operational parameters, which is essential for reducing your running costs.

Features & functions

- Home Page – instant overview of the compressor status

- Real Time Clock – allows pre-setting of compressor starting/stopping

- Second Pressure Setting

- Integrated Cooling and Dryer Control

- Fault History Log – for in-depth analysis

- Remote Control via Programmable Inputs

- Auto Restart after Power Failure

- Optional Base Load Sequencing

- SD Card – stores several run characteristics

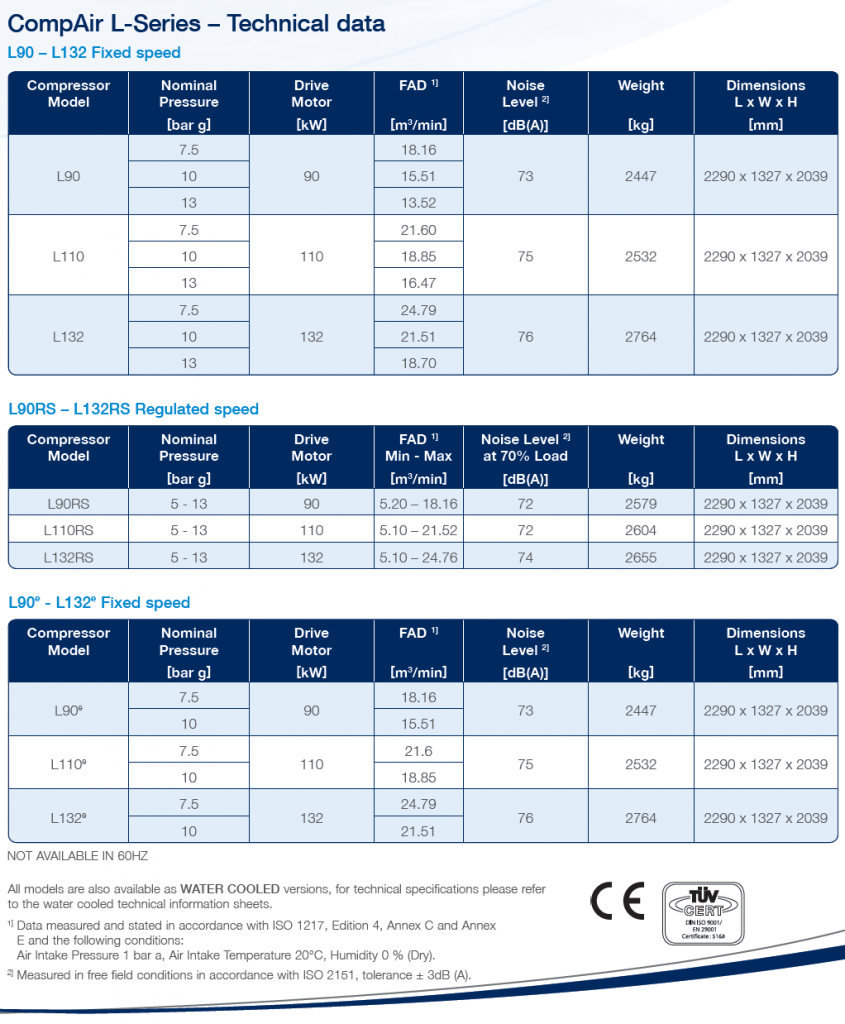

CompAir L-Series – Technical Data

L30 – L45 Fixed Speed

| Compressor | Nominal Pressure | Drive Motor | FAD1] [m3/min] | Noise [dB(A)] | Weight | Dimensions L x W x H | Integrated Dryer Option | Pressure dew [oC] | Weight |

|---|---|---|---|---|---|---|---|---|---|

| L30 | 7.5 10 | 30 | 5.75 5.01 | 67 | 887 | 1722 x 920 x 1659 | F30E (L30F) | 3 | 110 |

| L37 | 7.5 10 | 37 | 7.00 6.17 | 68 | 912 | 1722 x 920 x 1659 | F45E (L37F) | 3 | 120 |

| L45 | 7.5 10 | 45 | 8.00 7.00 | 69 | 953 | 1722 x 920 x 1659 | F45E (L45F) | 3 3 | 120 |

L30e – L45e Efficiency version, fixed speed

| Compressor | Nominal Pressure | Drive Motor | FAD1] [m3/min] | Noise [dB(A)] | Weight | Dimensions L x W x H | Integrated Dryer Option | Pressure dew [oC] | Weight |

|---|---|---|---|---|---|---|---|---|---|

| L30e | 7.5 10 | 30 | 6.00 | 67 | 954 | 1722 x 920 x 1659 | F30E (L30F) | 3 | 110 |

| L37e | 7.5 10 | 37 | 7.12 | 67 | 979 | 1722 x 920 x 1659 | F45E (L37F) | 3 | 120 |

| L45e | 7.5 10 | 45 | 8.67 | 67 | 1020 | 1722 x 920 x 1659 | F45E (L45F) | 4 3 | 120 |

L30RS – L45RS Regulated speed

Compair Delcos Xl Manuals Manual

| Compressor | Nominal Pressure | Drive Motor | FAD1] Min – Max | Noise Level2] at 70% load | Weight [kg] | Dimensions [mm] |

|---|---|---|---|---|---|---|

| L30RS | 5-10 | 30 | 1.33 – 5.53 | 66 | 925 | 1722 x 920 x 1659 |

| L37RS | 5-13 | 37 | 1.41 – 6.90 | 67 | 952 | 1722 x 920 x 1659 |

| L45RS | 5-13 | 45 | 1.41 – 8.02 | 70 | 974 | 1722 x 920 x 1659 |

1 Data measured and stated in accordance with ISO 1217, Edition 4, Annex C & E at the following conditions:

Air Intake Pressure 1 bar a, Air Intake Temperature 20°C, Humidity 0% (Dry)

Compair Delcos Xl Manuals For Sale

2 Measured in free field conditions in accordance with the ISO 2151, tolerance ± 3dB(A) Neo geo rom set download.

Filmora screen recorder for mac. 3 Data refer to ISO 7183, working pressure of 7 bar, inlet temperature 35°C and ambient temperature °C.

Downloads

The controller’s real-time clock enables users to start and stop their compressor at preset times. This allows the system to be pressurized prior to production, meaning users can have instant availability of compressed air.

The second pressure setting matches compressor flow to plant demand, reducing compressor idling, and also enabling two DELCOS XL units to be sequenced without the need for additional equipment.

The controller’s service diagnostics feature enables compressor inputs and outputs to be tested, and provides quick identification of any faults, which can result in reduced downtime. A detailed analysis of up to 64 faults can be stored by the controller, providing information including the time, date, temperature and pressure of the compressor when each fault occurred.

As well as on-site monitoring, the controller can also communicate with external interfaces, such as a PC, allowing for the remote control of the compressor, and in the event of a power failure, it can be set to automatically restart the compressor.

FUNCTIONS

- Home Page – instant overview of the compressor status

- Real-Time Clock – allows pre-setting of compressor starting/stopping

- Second Pressure Setting

- Integrated Cooling and Dryer Control

- Fault History Log – for in-depth analysis

- Remote Control via programmable inputs

- Auto Restart after Power Failure

- Optional SD Card – stores all run characteristicsCompressed air system can be easily optimized thanks to trends information

- Controlling and monitoring thanks to 6/5 programmable inputs/outputs

- Data logging and software update via optional SD card

- Service diagnostic feature

- Modbus as standard

- RS485 interface for Smart Air Master Sequencer

Base Load Sequencing (BLS)

Facts:

- With the optional RS485:3 module Delcos XL can act as a Base Load Sequencing Master device

- Up to 3 Slaves can be connected via a serial link to the Master (4 compressors in total)

- Supported Slave electronic controllers are Delcos 3100, Delcos Pro and Delcos XL

- Where any other compressor controller should be connected to the master a called Compressor Module (STD) can be installed into the Slave (fixed speed only)

- Available as retrofit kit or factory mounted

Benefits:

- Easy installation thanks to serial link to the Master.

- Supported Slave electronic controllers are Delcos 3100, Delcos Pro and Delcos XL

- Fixed speed compressors from other manufacturers can be connected as well.

- Easy to get complete overview about compressor sequencing group thanks to BLS page

- Easy to install afterwards thanks to retrofit kit